Uninterruptible Power Supply (UPS) systems are crucial for maintaining the reliability and stability of critical infrastructure. However, the batteries that power these systems can fail, leading to unexpected downtimes and potential data loss. Understanding the common causes of UPS battery failures and how to prevent them is key to ensuring your systems run smoothly.

High or Low Ambient Temperatures

UPS batteries are sensitive to temperature fluctuations. High or low ambient temperatures can significantly affect their performance and lifespan. A temperature above or below the optimal range of 20-25°C can lead to reduced capacity and accelerated ageing.

To prevent this, maintain a controlled environment for your UPS batteries. Ensure your server room or battery storage area has proper air conditioning and ventilation. Regularly monitor the temperature and adjust the HVAC settings as needed to keep it within the optimal range.

Poor Maintenance Practices

Neglecting regular maintenance can lead to a gradual decline in battery health. Issues such as loose connections, corrosion, and dust accumulation can compromise battery performance.

Implementing a routine maintenance schedule will work towards preventing this. This should include cleaning terminals, checking for corrosion, tightening connections, and ensuring the batteries are free from dust and debris. Regularly inspect and test the batteries to catch any potential issues early.

Overcharging or Undercharging

Incorrect charging is a common cause of battery failure. Overcharging can lead to overheating and swelling of the batteries, while undercharging can cause sulfation, where lead sulphate crystals form on the battery plates, reducing capacity.

For prevention, use a high-quality battery management system (BMS) to ensure proper charging. The BMS should provide accurate voltage and current regulation, preventing overcharging and undercharging. Regularly check the charging parameters and adjust them if necessary.

Ageing

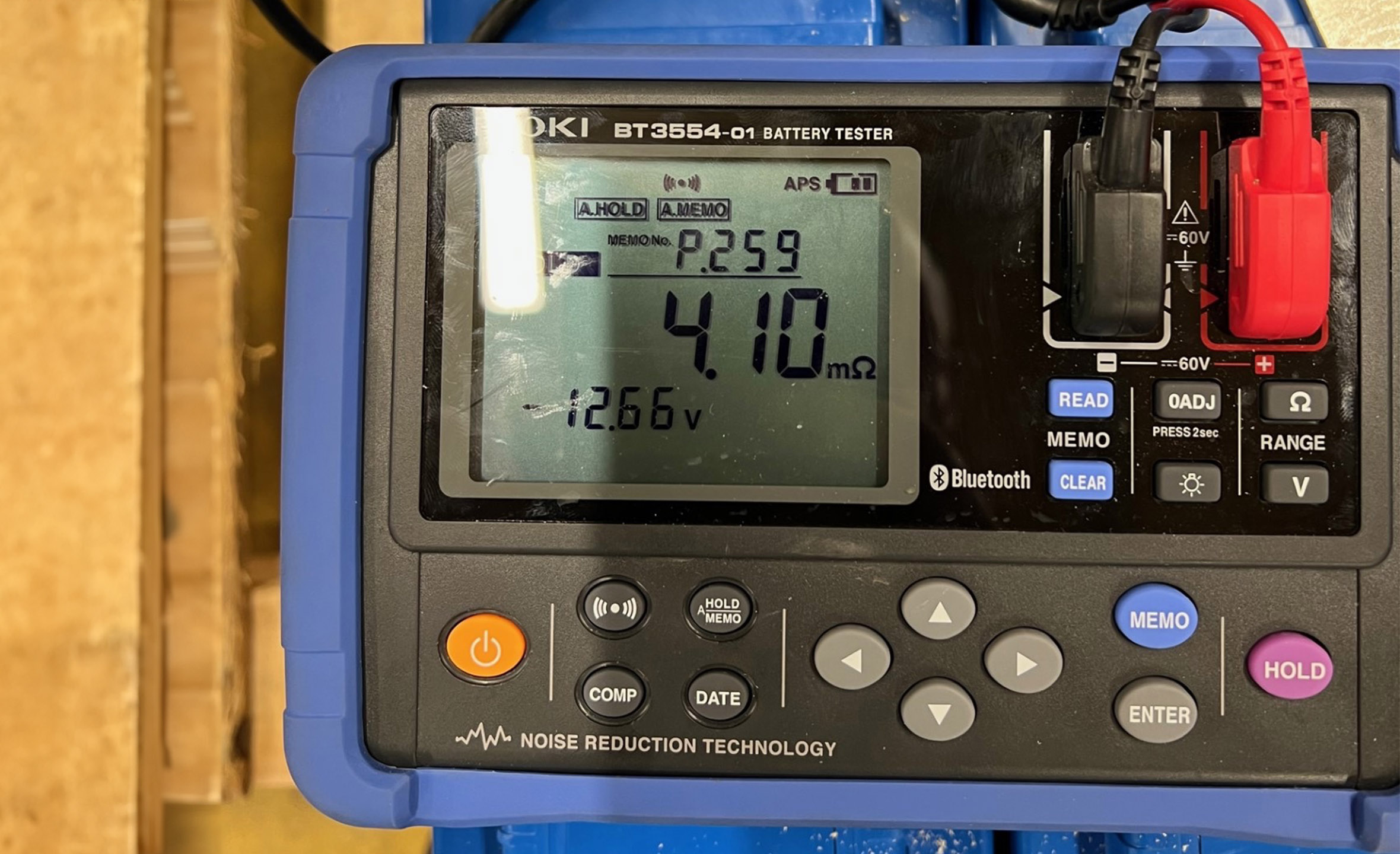

Over time, UPS batteries naturally degrade due to chemical reactions within the cells. This process, known as ageing, leads to reduced capacity and increased internal resistance, eventually causing failure.

Replacing batteries according to the manufacturer’s recommended schedule, typically every 3-5 years is best practice for UPS battery failure prevention. Regularly perform capacity testing to gauge the health of the batteries and plan for timely replacements before they fail.

Manufacturing Defects and Internal Short Circuits

Sometimes, batteries may have manufacturing defects or develop internal short circuits due to physical damage or quality control issues. These can cause sudden and unpredictable failures.

Ensuring you source UPS batteries from reputable manufacturers with stringent quality control measures. Regularly inspect batteries for signs of physical damage and perform impedance testing to detect internal faults. Implementing a battery monitoring system can provide real-time data on battery health and alert you to potential issues.

To conclude, preventing UPS battery failures involves a combination of proper maintenance, environmental control, and regular testing. By understanding the common causes and implementing preventive measures, you can extend the life of your UPS batteries and ensure the reliability of your critical systems.

For expert advice and professional UPS maintenance services, contact Barbour Consulting. Our team of experienced engineers can help you maintain the health of your UPS systems, ensuring uninterrupted power for your operations.