Unravel the mysteries behind battery block failures in UPS systems. Have you ever wondered why these crucial components often overlooked and forgotten items, falter, disrupting operations and potentially causing downtime in the event of a mains failure? Today, we delve into the root causes of battery block failures and unveil strategies for prevention.

Battery blocks can fail due to various reasons including high or low ambient temperatures, this can result in the available amps and their continuous delivery time becoming seriously affected once the blocks ambient temperatures goes higher or lower than 20 degrees. Other factors also influence the battery block performance are, age, sulfation of its internal plates, internal shorts, and manufacturing defects. These issues can lead to reduced capacity, increased resistance, and ultimately, failure of the battery block. Aging is a natural process where the battery’s performance deteriorates over time due to chemical reactions within the cells. Sulfation occurs when sulphate crystals build up on the battery plates, reducing the active material available for chemical reactions and leading to diminished capacity. Internal shorts can occur due to manufacturing defects or physical damage, causing a direct connection between the battery’s positive and negative terminals, which can result in overheating and failure.

To prevent battery block failure, proactive measures of UPS battery block testing and monitoring is essential. This can be performed as regular planned operative manual impedance testing or installing a battery monitoring system that constantly tracks the battery blocks impedance, temperatures and battery strings current flow The results are presented in easy-to-read graphics and alarms for early fault detection. Load bank testing is also a crucial method for evaluating the performance and health of UPS batteries. By subjecting the batteries to simulated loads, load bank testing helps identify weak or failing battery blocks before they cause critical issues. Additionally, routine maintenance, including visual inspections, temperature monitoring, and periodic capacity tests, can help detect early signs of battery degradation and prevent unexpected failures. Implementing a comprehensive battery testing and monitoring program, as recommended by industry experts, ensures the reliability and longevity of UPS batteries, minimising the risk of downtime and costly disruptions to critical operations.

We are factory accredited to supply, install and commission the Powershield range of battery monitoring products.

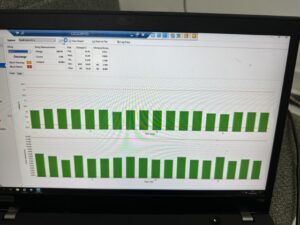

On a client’s site in Riyadh in the first week of April 2024, whilst performing load testing on one of the UPS systems, multiple battery blocs failed whilst performing a load autonomy test. This was discovered using the ‘live time’ Powershield Battery Monitoring system that tracked the voltages and the impedance failing on the individual blocks.

We immediately sourced new battery blocs in country then deployed a team to fly to site to swap out all the battery blocs. The new blocs were confirmed to have correct voltage and impedance when measured and a load test was made on the new strings whilst monitoring the discharge curve real time.

All performed as expected, very happy customer with the team on the night flight home to the UK ready for the next urgent deployment.